Menu

We will be happy to answer any question you may have.

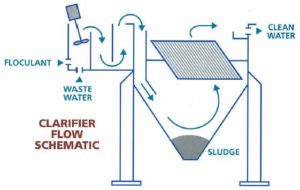

The flocculated water then flows over the first baffle, then under the second and finally flows to the body of the clarifier. The overflow/underflow allows time for the solids to gain size so that they settle out more easily. The wastewater is then directed to the bottom of the cone and back up through the plate pack. Some solids will settle as the waste stream makes its way to the clarifier cone. However, some particulate will be pushed up to the plate packs. The 60 degree angle of the plates provides a highly effective settling area in a small footprint. As some solids are forced up to the plate pack they start to settle upon each other gradually becoming heavier and ultimately slide down the plate pack to the clarifier cone. The clean water overflows from the effluent port and is suitable to proceed to the drain to city sewer or to an inspection tank. Sometimes a portion or all can be polished and reused. The clarifier sludge is then pumped from the bottom of the clarifier into a sludge thickening tank to feed a Met-Chem filter press.

The flocculated water then flows over the first baffle, then under the second and finally flows to the body of the clarifier. The overflow/underflow allows time for the solids to gain size so that they settle out more easily. The wastewater is then directed to the bottom of the cone and back up through the plate pack. Some solids will settle as the waste stream makes its way to the clarifier cone. However, some particulate will be pushed up to the plate packs. The 60 degree angle of the plates provides a highly effective settling area in a small footprint. As some solids are forced up to the plate pack they start to settle upon each other gradually becoming heavier and ultimately slide down the plate pack to the clarifier cone. The clean water overflows from the effluent port and is suitable to proceed to the drain to city sewer or to an inspection tank. Sometimes a portion or all can be polished and reused. The clarifier sludge is then pumped from the bottom of the clarifier into a sludge thickening tank to feed a Met-Chem filter press.Met-Chem, Inc.

837 East 79th St.

Cleveland, OH 44103

Phone: (216) 881-7900

Email: info@metchem.com

Copyright © Met-Chem, Inc