Menu

We will be happy to answer any question you may have.

We will be happy to answer any question you may have.

4. When do the cloths need to be cleaned or replaced?

The filter cake will begin to become wet, slimy and not as dry. This is your indicator that the cloths need to be cleaned. (see number 5 for cleaning info). If you have already cleaned your cloths and your process has not changed but you are still getting slimy filter cake, it may be time to replace your cloths. Cloth life varies from installation to installation and depends on such variables as frequency of cycles, proper cleaning and maintenance and the type of sludge that is generated. Generally speaking for most installations cloths can last up to 6 months at the most.

6. Can I expand my press for larger loading capacity?

Expansion depends on a couple of factors. First, if your press is already expandable, meaning you’re your press has a distance piece for expansion to a larger capacity, all you need to do is unbolt the distance piece and add additional plates in the 1-3 button sequence taking care that you add plates in even numbers. However, if you have a Met-Chem press or your press has notched and bolted sidebars, then it can also be expanded by removing the sidebars and replacing them with longer sidebars and installing additional plates. Please note that when adding plates, you must be sure to add them in the 1-3 button sequence in order to provide proper drainage.

9. What can I do to ensure the driest possible filter cake?

Be sure cloths are cleaned as needed and the air blow-down system is run for a full cycle. You may also wish to add a sludge dryer to your system. A dryer accepts filter press cake and dries it further to provide up to a 4:1 sludge reduction. (for more information on sludge dryers click the following link: www.metchem.com/sludge_dryer.htm

10. Why are there solids in my filtrate?

There are several possible causes. You might not have the proper cloths for you application or if you have been using the same cloths for an extended amount of time, you may have holes in the filter cloths. The gasketed cloth may have slipped out of the grooves. Or, perhaps, the cloth on the head plate may not be properly secured.

13. How do I precoat my filter press?

Precoat and bodyfeed are two related applications. Both of these special applications use diatomaceous earth (commonly known as D.E.), cellulose, perlite or fly ash, as a filtering aid when the solids in a slurry are extremely fine and free-filtering. The filter aid helps to trap the fine solids that otherwise might flow through the filter cloths. The processes of precoat and bodyfeed increase the clarity of the filtrate, provide for higher flow rates, more consistent runs, shorter cycles, dryer cakes, better cake release, and also help to protect and increase the life of the filter cloths.

The precoat process is performed before the slurry is pumped into the press. A precoat system consists of a tank, mixer and pump. The filter aid is mixed with water in the precoat tank. It is then pumped into the press where it coats the filter cloths. The filter aid rather than the filter cloths becomes your initial filter media.

During a body feed the filter aid mixes with the slurry in the holding tank prior to being fed into the filter press. The filter aid becomes part of the slurry thereby providing a better filter cake.

14. Why are my filter press plates leaking during the feed process?

If you have not made any recent changes to the plate stack (which is the number one reason this might occur), there are several possibilities.

You could have a build-up of solids on the sealing surfaces which will then need to be cleaned.

Check to see if the hydraulic pressure is set to the recommended specifications. If not, make the appropriate adjustment.

Another possibility is that there could be a wrinkle or hole in the filter cloth or the gaskets may be loose.

If you continue to have problems, contact your Met-Chem representative.

15. When should I replace my gaskets?

It’s a good idea to change your gaskets whenever you change your filter cloths. Also, if you are getting excessive leakage out of the press while maintaining correct hydraulic closure pressure, this may be a sign that it is time to change your gaskets.

Gasket life will depend on many factors, such as length of filtration cycle, temperature, and excessive closing force. Gasket replacement should take place if the gasket appears to be delaminating or shredding. Also, if excessive temperatures exist and cycles are very long, the standard gasketing material may go into additional cure, causing it to harden slightly. If you continue to have a problem, contact your Met-Chem representative for an alternative.

16. How do I change my gaskets?

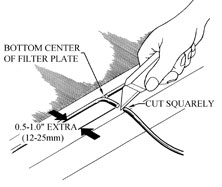

- Insert the gasket starting at the bottom center of the filter plate using a wood or plastic mallet. Push the gasket into the groove around the outer edge of the plate until it mates at the center of the plate. Many installers will incorrectly stretch the gasket material. This reduces the cross section, making it easier to insert. However, by stretching the gasket material for easier installation, it has a tendency to creep and open the butted joint of the gasket, causing a leak.

- Cut the gasket approximately 1/2″ (12mm) to 1″ (25mm) longer than required, cutting the end squarely.

- Apply one or two drops of Eastman 910 (or equivalent “super glue”) to one end of the gasket and quickly join it to the other end. Hold it under hand pressure for approximately 30 seconds. Then crowd the excess gasket into the groove to ensure fullness of gasket material.

Install the discharge eye gaskets in the same manner.

NOTE: When gasketed plates are first put into use, the new gasket material may be slightly sticky or gummy and cause gaskets to pull out of the grooves when plates are separated. This condition is eliminated as the product film is built up. If any gaskets show this characteristic, apply a silicone spray until the press has been used several times.

17. How do I change the center feed assembly?

If the press is leaking (around the locknut on the 470mm size or from the bottom leg drain holes on 630mm and larger size presses) during the start-up of the feed process, the problem is usually leakage past the center feed quad ring seal. The quad ring may not seal for several reasons.

First check for the cause:

Did the locknut on the outside of the press head loosen during shipment? If so, tighten the locknut using a spanner wrench, pliers, or pipe wrench.

18. How often should I change the oil in my hydraulic system?

Under normal conditions, you should usually change your hydraulic oil once a year, or every 2,000 operating hours. Under severe conditions, the oil will need to be changed more frequently. The following chart is a guideline for maintenance of your hydraulic power unit:

Item | Frequency | Procedure |

|---|---|---|

| Clamp Pressure | Daily | Check for correct clamp pressure. |

| Relief Valve | Quarterly | Check for proper setting. |

| Oil Level | Weekly | Check for proper level. |

| Oil Filter | Monthly | Inspect and/or clean. |

| Oil Filter | Yearly | Replace. |

| Hydraulic Oil | Yearly | Replace. |

Met-Chem, Inc.

837 East 79th St.

Cleveland, OH 44103

Phone: (216) 881-7900

Email: info@metchem.com

Copyright © Met-Chem, Inc